Process Automation

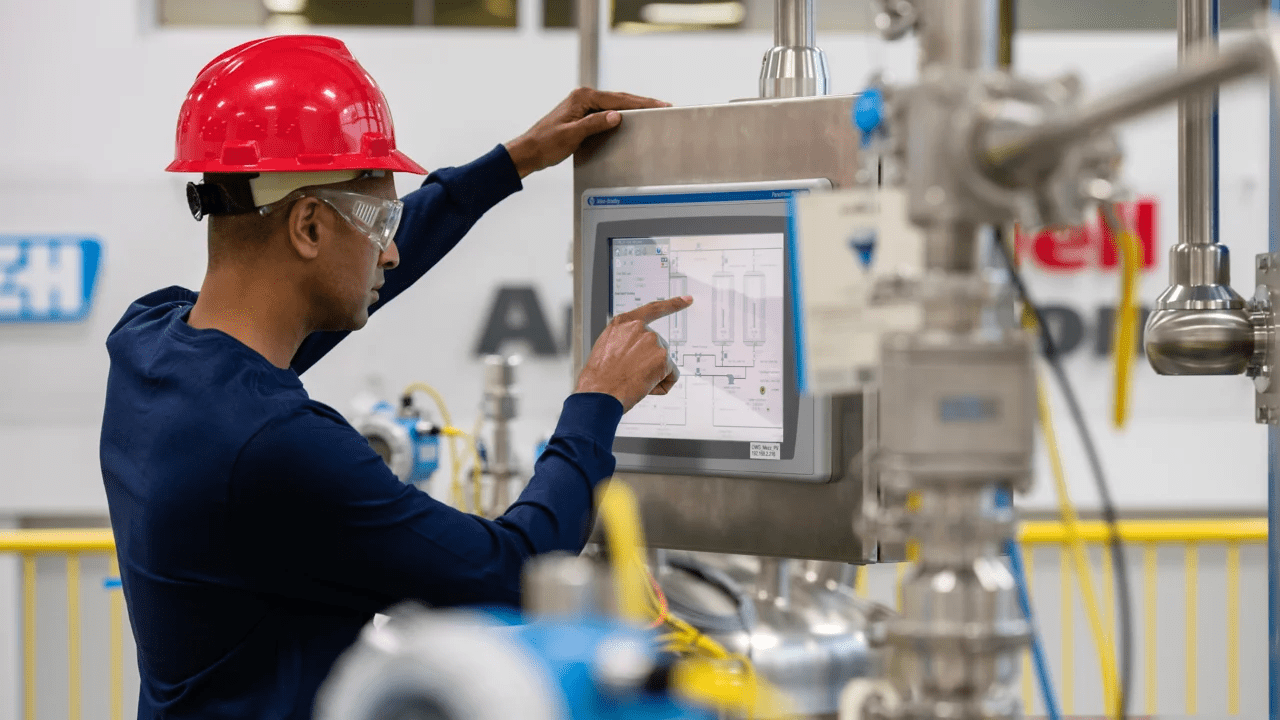

Process Automation

Seqronics specialises in providing complete turnkey Electrical & Automation Solutions for most manufacturing & process plants such as Automotive, Textile & Paper, Food & Beverages, Machine Manufacturing, Pharma & Utilities (Energy, Gas & Water), Chemical & Polymer, Cement, Steel & Forging Industries.

We offer complete service for system design, software development and commissioning of plant and machine control systems including development of functional specifications, PLC software, plant floor operator interface devices, industrial automation communication networks & system documentation. Our Automation service engagements range from supporting our clients on individual projects to establishing multi-disciplinary teams to support them on an on-going basis. Our team is equipped with a good understanding on various automation systems like PLC, HMI, Robotics, Drives, SCADA, etc. We provide Engineering services for various platforms like Siemens, Rockwell Automation, Schneider Electric, Mitsubishi, Delta, AutoCAD, etc.

Apart from the core automation capabilities, Seqronics also has expertise in implementing Manufacturing & Process Intelligence systems, a rapidly growing business requirement that connects enterprise level and plant floor systems.

Seqronics provides Design, Engineering, Supply, Installation and Commissioning of Redundant/Non-redundant PLC & SCADA control systems. Our standardised systems design approach include the following activities,

- Front end & Detailed Engineering design (Concepts & Detailing).

- Designing of System Architecture & Process Flow Diagram.

- Preparation of specification & BOM for procurement assistance.

- Functional Schematics & Loop diagram preparation.

- Document preparation for as-built Drawings, O&M Manuals, Printing, compiling etc.

- Application Software Development of PLC, SCADA, etc.

- Factory Acceptance Test & Validation.

- System Integration & Configuration work.

- Installation & Commissioning Support.

- Training & Consultancy Services.

Our Services include,

- Upgradation of PLC system, upgrading existing / semi-automatic plants to total automatic systems.

- Software logic conversion from existing to latest software.

- Integration with MES/ERP System.

- Project Engineering & Management

- Software Development & Technical Support

- Process Optimization, HMI & SCADA monitoring systems

- Business solutions involving 3rd party connectivity solutions

- Field Engineering & Electrification

- Annual Maintenance Contract (AMC)

- Documentation i.e. Control system configuration drawings, FDS, QC, data sheets, UPS

- Capacity calculation, Heat load calculation, etc.

- Remote Troubleshooting Support

INDUSTRIES WE SERVE

AUTOMATE TO

INNOVATE

AUTOMATE TO

INNOVATE

Textile Industry

Sugar Industry

Paper Mills

Food & Beverage

Pharma & Life Science

Chemical Factories

Rubber, Plastic & Polymer

Water & Waste Water treatment

Solar Power Plants

Steel and Forging

cement industries